For sale: Advanced vertical farming system featuring two climate cells totaling 288 m² of growing space. This highly automated system is designed for efficient production of leafy greens, herbs, microgreens, and more, with a capacity of up to 33,000 kg/year. Fully equipped with state-of-the-art LED lighting, irrigation, seeding, harvesting, and cleaning systems, this turn-key farm is ideal for year-round production.

[Confidential Listing]: Fully Automated Vertical Farming System for Sale – Located in the Southern Ontario Area

This advanced Vertical Farming System offers a fully automated, high-efficiency solution designed to grow a wide variety of crops including leafy greens, herbs, microgreens, soft fruits, young plants, and small plants. The system features two (2) climate-controlled cells with a total of 288 m² of growing space, ideal for year-round indoor production. The system is specifically configured for the production of 100g heads of whole leaf lettuce, with the potential to produce up to 33,000 kg/year (~95 kg/day) of lettuce. However, it is adaptable for other crops by modifying tray configurations.

Configuration:

- Climate Cells: The two 6-level automated cultivation cells, each offering 144 m² of growing space, are equipped with conveyors, elevators, and space for 120 containers per hour. The layer height of 400 mm provides free space for optimal plant growth.

- Lighting: The cells feature 180 LED lights per climate cell (Signify Dynamic G4 GPL PM 210 DRBWFR L150 G3.0 C4, 88W each) with efficacy of up to 4umol/J. There are 6 LED control areas, one per layer, allowing for precise light intensity adjustments up to 250 μmol.

- Temperature and Humidity: The system operates within a temperature range of 15-26°C and a relative humidity range of 55-90%, ensuring the ideal conditions for crop growth.

- Irrigation: An advanced ebb and flood irrigation system controls water and nutrient delivery, supported by one irrigation recipe with controls for pH and EC.

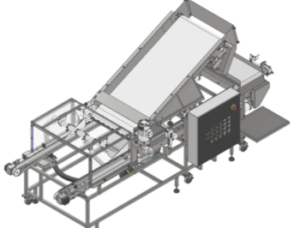

Seeding and Harvesting:

The system is equipped with a fully automated seeding station, featuring:

- Infeed Conveyor

- Drum Seeder (Flier Systems) that can seed 500 trays per hour with two seeding drums.

- An irrigation module ensures optimal water delivery, and an outfeed conveyor moves trays to the next step.

For harvesting, an automated band-saw cutter with a 600mm cutting width handles up to 2400 trays per hour, optimizing workflow and reducing labor costs. The harvesting conveyor extends to 4000 mm in length, providing ample space for post-harvest handling.

Logistics and Conveyors:

- The system can manage up to 200 containers per hour using a sophisticated internal transport system.

- Additional logistic conveyors and a crate loop for handling 200 crates per hour, combined with weighing stations and dirt collection bins, streamline post-harvest processes.

Washing and Cleaning System:

The system features an advanced washing and cleaning module that includes:

- Tray Placing Robot

- Root Cutter Module

- Tray Cleaning and Washing Modules

- Tray Flip Down Module

- Container Washer and Buffer Modules (capacity for 200 trays/hour and 50 benches/hour).

Water Management & Irrigation:

A comprehensive water and nutrient management unit handles day-to-day irrigation needs with:

- Day Storage Water Silo (1X 21 m³)

- Fresh Water Silo (13 m³)

- Drain Silo and Transport Pump

- UV-disinfection Unit with 250 mJ/cm² UV dose capacity. It can process 4.4-5.0 m³/h of drain water or 7.4-8.4 m³/h of fresh water.

- The system also includes a hydrophore unit and irrigation pipework with complete control software.

Transplanting and R&D Chamber:

The system includes a transplanting table for manual transplanting and a growing chamber for R&D and growing recipe development. The R&D chamber has the following dimensions:

- Dimensions: 2500 X 5250 X 3300mm

- Temperature Range: 12-35°C

- Relative Humidity Range: 50-90%

Tooling and Maintenance:

- A Tooling Kit is provided for system installation and maintenance.

- Additional Sensors include:

- 1X CO2 sensor

- 4X Water sensors per cell

- 12X Electrical energy sensors

- 4X Cold energy sensors

Included Containers & Trays:

- 300X Containers (1650 X 625 mm)

- 120X Germination/Propagation Trays (187 plugs/tray, 400 X 600mm)

- 325X Propagation Trays (96 plugs/tray, 400 X 600mm)

- 780X Cultivation Trays (12 plugs/tray, 400 X 600mm)

Additional Farm Logistics:

- 4X Automatic Conveyor Belts

- 1X Pivot Point

- 1X Container Buffer Zone

- 1X Tray Buffer Zone

- 1X Aluminum Bridge Station

System Location & Shipping:

The system is currently located in the southern Ontario area and 12 of 14 containers are available for pick-up with two containers available for shipment to the buyer’s location under DAP (Incoterms 2020). The buyer will be responsible for the cost difference if shipping is required from sellers location.

Contact chris@secondbloomauctions.com for more pricing and more information.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.